You should spend about 20 minutes on this task.

The diagram below shows how oil is extracted in the production of perfume. Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

You should write at least 150 words.

Sample Answer 1

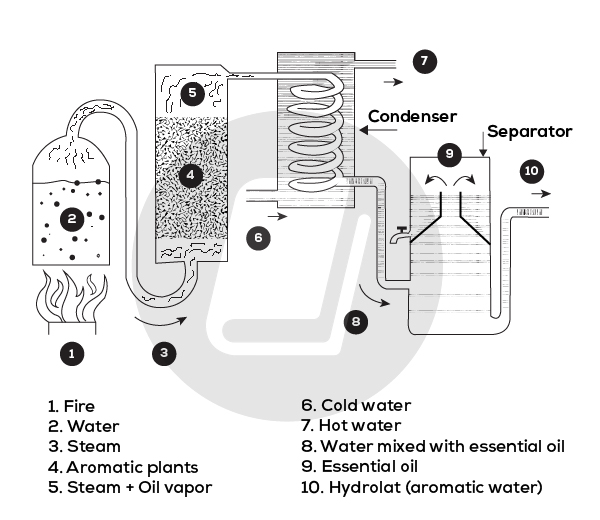

The diagram delineates the linear man-made process of manufacturing perfume from aromatic plants. Overall, four primary steps are involved, beginning with boiling the input material and culminating in the refined essential oil.

With respect to the first two steps, a heat source is used to boil water in an airtight cooker to produce steam, which is then directed via a tube to a larger container where aromatic plants are heated. The hot steam from the boiler serves as a vaporizer to extract essential oil from raw plant materials, and then the mixture of steam and oil vapour is transferred to another cylinder for the next step.

In the third step, the mixture is liquidized in a spiral condenser cell, with cold and hot water at the bottom and top of the container. Afterwards, the solvent is moved to a separator, where the oil is removed, culminating in the refined essential oil.

Sample Answer 2

The diagram illustrates the process of extracting oil in the manufacture of perfume. Overall, this process has ten stages, beginning with the generation of heat and ending with the production of hydrolat (aromatic water).

In the first two stages, a cylinder of water is brought to a boiling point when the water is heated. The resulting steam is then passed through a pipe to another cylinder. Next, this steam passes through aromatic plants located in this second cylinder. After the steam passes through, a mixture of steam and oil vapour rises to the top of this cylinder.

At stage six, the mixture of steam and vapour is passed through a third cylinder, where a coil is immersed in cold water, allowing the mixture to condense. Hot water is extracted through an outlet pipe during this condensation stage, shown as stage seven in the diagram. Then, water mixed with essential oil passes to a separator. The oil remains on the surface while aromatic water is drained from the separator through another pipe.

Sample Answer 3

The diagram illustrates how perfume is made using the distillation technique, which utilizes the capacity of water vapour to capture the essence. Overall, there are four main stages in this complex process, starting with boiling water and ending with distilling essential oil.

First, water is heated at a high temperature in a tank placed on a flame. As the water boils, the vapour is collected and sent through a pipe connected to the bottom of another tank called the distillation chamber. Aromatic plants or flowers are put on the upper part to be steamed. When the vapour rises to the top of the chamber, it collects fragrant molecules and forms a mixture that then goes through a coil for condensing. The coil is placed in a tank with a cool-water inlet at the bottom and a hot-water outlet at the top, allowing warm water to flow.

Once the mixture of vapour and essential oil has been cooled down by cold water, it condenses and becomes….

Sample Answer 4

The picture demonstrates how essential oil is extracted using the steam distillation method in a perfumery manufacturing facility to produce perfume.

Overall, the presented linear process involves relatively straightforward steps, beginning with boiling the input material and culminating in the refined essential oil. It is worth noting that a connecting extraction tube channels the hot steam and circulates the oil thoroughly before the final product travels downward to the oil container.

The perfume-making procedure begins with placing a boiler over a heat source that traps hot steam and water. After that, the steam extracted from the boiler facilitates the vaporization process in the second container. At this stage, steam increases the tube’s temperature, allowing aromatic raw plant materials to mix and produce oil.

The vaporized oil is then transported to a condenser cell, where the oil condenses into liquid and is collected via a spring-shaped tube. In the final step, the oil is poured as droplets into a bottle containing condensed water.

Sample Answer 5

The diagram provides an illustration of how essential oil is used in a perfumery manufacturing system to produce perfume.

Overall, it can be seen that the given process consists of four main stages, starting from boiling the input water and ending with the culmination of the refined hydrolat.

The perfume production begins with a water container being placed over a heat source using fire. The boiling water evaporates, releasing hot steam which will be transferred to the second container via an extraction tube. At this stage, steam increases the temperature of aromatic plants, letting the raw materials produce oil then trap the mixture of steam and oil vapor within.

The production process continues with the vaporized oil being transported to a condenser cell where this product is condensed and delivered using a spring-shaped tube. At the same time, on both ends of the cell contains hot and cold water supplied from two different tubes to support the condensing process. At the last step, water mixed with essential oil will be transported to a separator that filters the oil, allowing hydrolat, known as aromatic water, to culminate via an extraction tube.