You should spend about 20 minutes on this task.

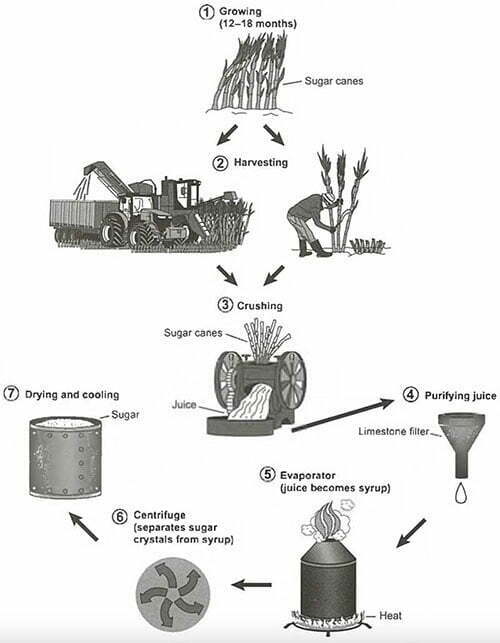

The diagram below shows the manufacturing process for making sugar from sugar cane.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

Write at least 150 words.

Sample Answer 1

The illustration outlines different steps of producing sugar from sugar cane. As delineated in the diagram, sugar cane plants get ready to be processed for manufacturing sugar when they are over one year old. The process involves harvesting, crushing, syrup, centrifuging, drying and cooling.

As the diagram depicts, sugar cane plants are harvested from the fields at least one to one and a half years old to make sugar from them. They are harvested either manually by human labourers or by using machines. In the third step, these sugar canes are crushed in a crusher machine to produce juice. Afterwards, the produced juice is purified by a limestone filter before an evaporator heats the juice to create the syrup. Sugar crystal is separated from the syrup in a device called a centrifuge. The final step involves drying and cooling the produced sugar crystals to make the sugar we consume.

Sample Answer 2

The picture diagram illustrates the phases involved in producing sugar from sugar cane plants.

Generally speaking, sugar production involves seven main stages that start with growing the sugar cane on farms and culminates in drying and cooling the crystal syrup to form sugar that is ready to be consumed.

As the process diagram suggests, in the first step, the sugar cane plants are harvested from the farmland when they are about a year to eighteen months old. The harvesting of sugar cane plants is done either manually or with the help of agricultural machinery. After that, the sugar cane stalks are crushed in a grinder, forming sugar cane juice.

Afterwards, this juice is purified with the use of a limestone filter. Subsequently, the juice is heated in an evaporator device. During this step, the vaporization of water creates the syrup, which is then poured into a centrifuge machine, which separates sugar crystals from the syrup. In the final stage, the created crystals are dried and cooled to manufacture the final product- sugar.

Sample Answer 3

The diagram displays how sugar is manufactured from sugar cane. Overall, it is a linear process consisting of four main stages: farming, crushing, separating and drying.

The first step is to grow sugar cane; it takes about 12 to 18 months to mature. After it has fully grown, it is harvested either manually or mechanically. The manual method involves farmers removing the leaves and chopping the canes, while the mechanized method uses machines to cut the canes directly.

The harvested canes are then crushed in a mill to extract the juice, purified using a limestone filter. Next, the purified juice is boiled in an evaporator to remove water, which concentrates it into a syrup. The syrup is centrifuged and spun at high speed to separate the sugar crystals. Finally, the crystals are dried and cooled, and the end product is sugar.

Sample Answer 4

The way sugar is made from sugarcanes in the sequence is portrayed in the given diagram. Overall, this seven-step process starts with growing sugarcanes to making crystalline sugar.

In the first step, sugarcanes are grown in appropriate fields. By around 12 to 18 months of its cultivation, the canes are harvested manually or by machines. The harvested canes are then sent for crushing in a rolling machine. This machine extracts the sugarcane juice, which is collected in containers.

The next primary step is purifying the extracted juice in a limestone filter, and the clear juice is later transferred to a large, funnel-shaped evaporator. This is heated thoroughly from the bottom until the juice transforms into syrup. The most crucial step in manufacturing sugar is centrifuging, which is how the sugar crystals are separated from the syrup. These crystals are initially dried and then cooled, and eventually, sugar is made.